ofis oil film thickness measurement|oil film thickness chart : chain store The OFIS is our hand-held measuring device for mobile oil film thickness measurement. Measuring the oil film on metallic surface areas in just a few seconds. Dom Carlos Alberto Breis Pereira ou, como gosta de ser chamado, D. Beto, é o 4º bispo da Diocese de Juazeiro (BA). Ele que é um Frei Franciscano, nascido em São Francisco do Sul, veio ser bispo às margens do rio São Francisco, exatamente no tempo do Papa Francisco. Tanta coincidência pode ser lida também como um sinal de Deus, nos .

{plog:ftitle_list}

WEB29 de mar. de 2022 · Desde o lançamento de PlayStation Plus em 2010, a SIE tem estado na vanguarda da inovação com serviços de assinatura de jogos. Temos orgulho de .

The OFIS is our hand-held measuring device for mobile oil film thickness measurement. Measuring the oil film on metallic surface areas in just a few seconds.

Oil Film Thickness Measurement Easy, Fast and Objective The OFIS 2.0 is a handheld measuring device for mobile oil film measurement designed for rough industrial environments. .

Oil Film Thickness Measurement Easy, Fast and Objective The OFIS 3.0 is a handheld measuring device for mobile oil ilm measurement designed for rough industrial environments. .

Measuring Oil-Film Thickness on a Coil or Sheet Surface. The oil film on the surface of a coil or sheet finds use as a coolant and lubricant in the rolling process; acts as an . The measurement of oil film thickness in cams is crucial for maintaining optimal performance and reducing wear. By analyzing the cam lift data, you can: Determine the minimum oil film thickness: The minimum oil film thickness is a critical parameter that indicates the risk of direct metal-to-metal contact and potential wear.The classic method of measuring the oil film thickness on an oiled sheet metal is completed offline, in a laboratory, using gravimetric analysis (known in the . The OFIS, a portable oil film measuring device, is de-veloped on the same measuring principle as the OFM. This device allows the oil layer in problematic areas on coils, blanks, and .AMEPA measuring technology represents more than 35 years of experience in the steel, aluminium and automotive industries. Reliable, durable, innovative.

In lubricated systems, monitoring the thickness of the lubricating film layer is fundamental to guaranteeing the correct functioning of mechanical components and equipment [22,23].One of the main difficulties for real-time monitoring of the lubricating film layer is the complexity involved in developing non-invasive systems that can be directly applied to . The oil film thickness is a crucial parameter reflecting the lubrication status of bearings, directly influencing the operational state of bearing transmission systems. However, it is challenging to accurately measure the oil film thickness under traditional disassembly conditions due to factors such as bearing structure and working conditions.

Oil Film Thickness Measurement Easy, Fast and Objective The OFIS 2.0 is a handheld measuring device for mobile oil film measurement designed for rough industrial environments. With the OFIS 2.0, the oil layer on metal-lic surfaces can be inspected within a few seconds. By utilizing the OFIS, a time-consuming gravimetric or There are few experimental results available on film thickness at speeds above 5 m/s and they are almost all based on the optical ball-on-disc test rig. In contrast to the contacts in a rolling bearing, in which the lubricant in the oil reservoir distributes symmetrically, ball-on-disc contact shows asymmetry of lubricant distribution due to centrifugal effects. In order to closely . A schematic of the ultrasonic technique applied to oil film thickness measurement is shown in Fig. 1, where a pulse is released by an ultrasonic transducer and is incident on a three-layered sandwich structure, with the echo pulse reflected and received by the same transducer.The ratio of the echo pulse to the incident pulse is known as the ultrasonic .

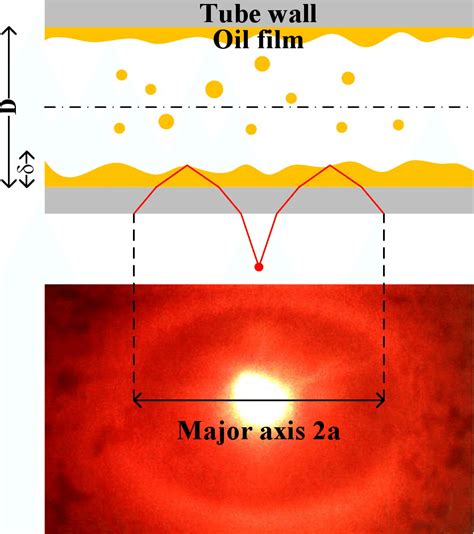

This paper describes advances in using laser-induced fluorescence of dyes for imaging the thickness of oil films in a rotating ring tribometer with optical access, an experiment representing a sliding piston ring in an internal combustion engine. A method for quantitative imaging of the oil-film thickness is developed that overcomes the main challenge, the accurate calibration of . Roller bearings support heavy loads by riding on an ultra-thin oil film (between the roller and raceway), the thickness of which is critical as it reflects the lubrication performance. Ultrasonic interfacial reflection, which facilitates the non-destructive measurement of oil-film thickness, has been widely studied. However, insufficient spatial resolution around the rolling .The use of laser-induced water Raman backscatter for remote thin oil film detection and thickness measurement is reported here for the first time. A 337.1-nm nitrogen laser was used to excite the 3400-cm−1 OH stretch band of natural ocean water beneath the oil slick from an altitude of 150 m. The signal strength of the 381-nm water Raman backscatter was always . Subsequently, the center oil film thickness of the contact region is calculated by Eq. 10. Fig. 6 shows the means and standard deviations of center oil film thickness for six tests. The calculated mean of center oil film thickness gradually increases with the increment of rotation speed and agrees well with the theoretical results [50], [51 .

hercules refractometer adjustment chart

Semantic Scholar extracted view of "Measurement of oil film thickness : The fluorescence method and others" by S. Sanda. Skip to search form Skip to main content Skip to account menu. Semantic Scholar's Logo. Search 221,892,231 papers from all fields of science. Search. Lubricant film thickness is the most informative variable that reflects lubrication conditions and transmission efficiency in the mechanical equipment, therefore its measurement is highly important. Despite a large number of theoretical models that have been developed to describe the lubricant film, complexities and uncertainties in a real tribo-pair contact still hinder .

The ultrasonic technique is very effective in measuring lubricant film thickness in a noninvasive manner. To estimate the film thickness with reflection signals, two main ultrasonic models are often applied in cases of different film thicknesses; they are the spring model for thin films and the resonant model for thick films. However, when measuring oil film thicknesses .

Upon returning to their original state, photons of a different frequency are emitted and can be correlated to oil film thickness. 25–28 Electrical capacitance probes and inductance probes can be mounted flush on .

hercules refractometer and ph meter

DOI: 10.1016/j.triboint.2021.107290 Corpus ID: 240539560; Review of ultrasonic-based technology for oil film thickness measurement in lubrication @article{Dou2022ReviewOU, title={Review of ultrasonic-based technology for oil film thickness measurement in lubrication}, author={Pan Dou and Yaping Jia and Peng Zheng .measure the oil film thickness in the range of 10~100 m, and the spring model [ 7] is powerful in measuring oil film thickness below 10 m. Since the spring model was proposed by Drinkwater in 2003, the ultrasonic methods were then extensively used to measure oil film thickness in various tibological compo- First the nominal viscosity was varied (M32 and M460). Different chemical structure were tested using a naphthenic oil NlOO and a poly-alphaolefin PAO. Both oils have the some nominal viscosity (IS0 V G 100). Fig. 3 Sensor for Film Thickness Measure: ments (Film Profile). Fig. 3 shows the geometry of a sensor for film thickness measurements.EMG SOLID® is a system for the up-to-date online measurement of oil deposits on running strips, . Dry film thickness measurement with EMG SOLID® DFT. EMG SOLID® DFT (Dry Film Thickness) uses laser-induced fluorescence spectroscopy to check the basis weight of the transparent and low-pigmented coating layer on electrical steel.

Findings. Measurement and calculation of oil film thickness in a ball bearing are carried out under various rotating speeds and external loads. By comparing the calculated capacitances with measured results, it can be concluded that the calculated results obtained by the amended film thickness formula are much closer to the test findings than the classical . Ultrasonic method is promising in oil film thickness measurement, while the commonly used commercial transducers are bulky and then sometimes hinder the application of this technology in field. Using the piezoelectric element is an alternative method and has the advantage of being convenient to be fixed. In this work, the key points of the use of the . The experimental apparatus shown in Fig. 4 was constructed to generate a steel–oil–steel system with a range of known oil-film thicknesses and allow measurement of the ultrasonic reflection coefficient. An oil-film (Shell Turbo T68 mineral oil) was formed between a 60×20×30 mm 3 top steel plate and a 6×20×5 mm 3 bottom steel plate. Both the bottom .Oil Film Thickness Measurement Automotive Oil Film LevelDescriptionA top marine engine manufacturer commissioned MTI Instruments to design and manufacture a non-contact sensor to measure the microscopic oil film layer between the engine cylinder wall and the piston ring.¬†Engine testing is (815) 838-0005.

oil film thickness chart

THE use of Newton rings for the measurement of oil film thickness in point or line contact is rendered difficult by the similarity of the refractive index of normal glass and oil. For this reason it is usually applied when the lubricant is not oil (Skinner1 used glycerine) or when one of the surfaces is not glass. Recently, Kirk2 has used interferometry with ‘Perspex’ ; this limits the .The performance of ultrasonic oil-film thickness measurement in a ball bearing is quantified. A range of different viscosity oils (Shell T68, VG15, and VG5) are used to explore the lowest reflection coefficient and hence the thinnest oil-film thickness that the system can measure. The results show a minimum reflection coefficient of 0.07 for .

The film thickness measuring device is used for the application measurement of various lubricants such as oil, hotmelt or Drylub, within the context of quality control, as support for problems in manufacturing, for process optimisation, etc. The measuring device is suitable for a multitude of materials and surfaces (cold and hot coils, hot-dip .

oil film coil thickness

heska veterinary refractometer

Resultado da 30 de ago. de 2023 · Priori Diagnósticos. 21 Reveja Av. República do Líbano, n 966 - St. Aeroporto, Goiânia - GO +55 62 3223-8398 .

ofis oil film thickness measurement|oil film thickness chart